Göttingen Microfluidics Facility

The Microfabrication Facility at the Max Planck Institute for Dynamics and Self-organization in Goettingen provides assistance in the design and training in the use of PDMS and PMMA microfluidic devices.

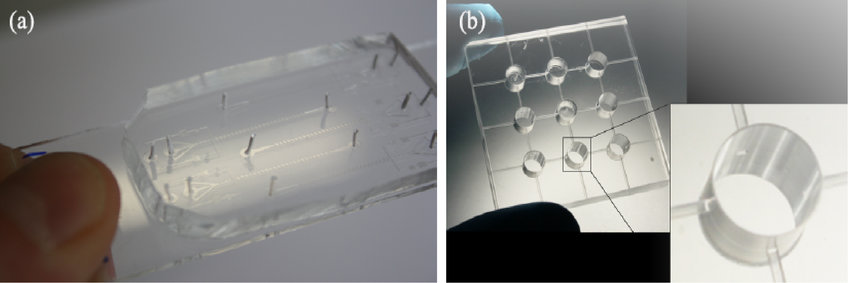

PDMS based microfluidics, with feature sizes ranging between 5 and 200 microns are generated by molding PDMS on silicon wafers containing photoresist patterns. These patterned wafers are generated in our 35 m2, class 1000 clean room. Within the clean room is a spin-coater for depositing well-defined uniform layers of photoresist (SU-8 or AZ), hotplates for baking the resist, and a mask aligner (EVG-620) for exposing patterns on the layers of photoresist. A white light interferometer (Wyko NT1100) is used to accurately measure the heights of the structures. Once the replica mold is generated, the steps of soft lithography, i.e. molding the PDMS and assembling the microfluidic devices, can be conducted off-site. Besides soft lithography, the institute is equipped with a high-precision milling machine (DMU 50, DMG Mori Seiki) which is used to pattern microchannels in hard plastics like PMMA and metals with feature sizes ranging between 150 microns and 10 cm. By heating the PMMA above the glass transition temperature, microfluidic channels can be assembled.